OBD2 to Gantner Q.station

Gantner Instruments measuring systems currently run in a large portion of the automobile industry in a big variety of applications including engine and vehicle test stands. Customers often sent the request to read data from the engine control unit (ECU) via the On-Board-Diagnostics interface (OBD2).

The OBD2 protocol is a standardized protocol to enable monitoring organizations to access relevant measuring channels of the ECU.

Engine coolant temperature, RPM, ignition timing, injection amount and other channels are available through this protocol.

While the protocol used other bus architectures like the K-line in the early days, the OBD2 protocol now usually uses the CAN bus of modern vehicles.

The Gantner Instruments Q.station 101 T has a CAN interface and a programmable realtime core, which is able to utilize the interface to send queries using the OBD2 protocol to get the standard OBD2 data from the ECU.

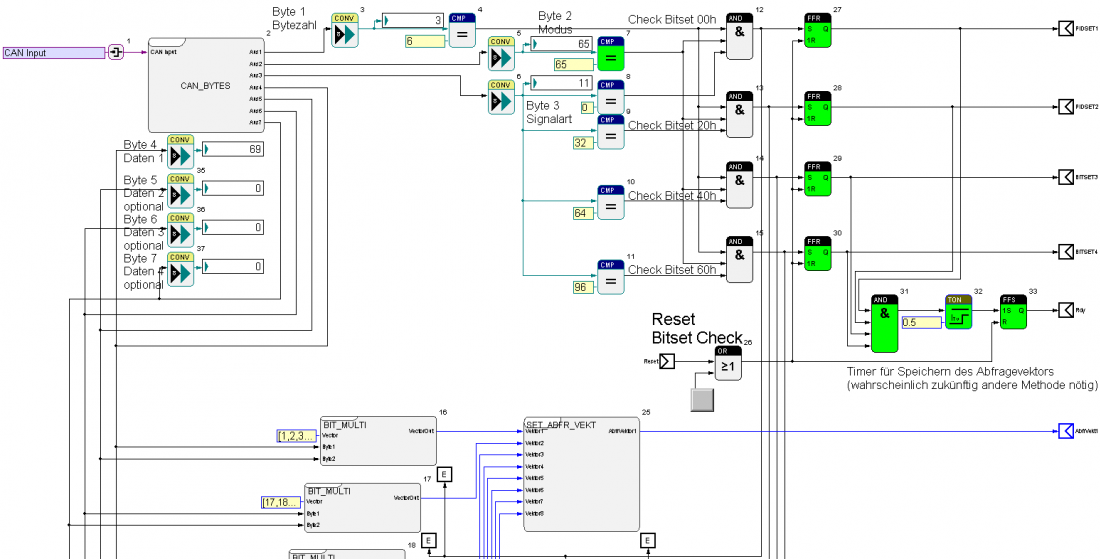

To reduce the load on the ECU and to not send queries about measuring channels that do not exist in this specific ECU (there are not many vehicles with eight lambda probes) we built a routine, which only sends queries for measurement channels that actually exist in the ECU.

To accomplish this task, we first need to send a query about the available channels to the ECU. The ECU then answers with a 32-bit status field.

We then calculate this status field into a query array. After getting all information about the available data, the program starts cycling through this array of queries. The user sets the time between queries.

The Q.station can display and store the acquired data together with the measuring channels of the Gantner IO modules for prospective analysis.