Usage of Q.brixx-based systems at the Bosch Thermotechnik GmbH

Bosch Thermotechnik GmbH, in D 73249 Wernau, currently uses 3 Q.brixx-based systems to simulate heating systems. In addition, there will be 3 more systems in 2017. For 2018, further 7 systems will be procured.

The hardware solution consists of:

- Qbrixx2 station 101DT for measuring temperatures (flow, return, storage, outside temperature sensor, ...) via Q.brixx A104 TCK or Q.brixx A107 and sensors with an analog output via Q.brixx A108.

- A resistance matrix for temperature simulation via CAN

The necessary application for the measurement system Qbrixx has been realized by the ProSign GmbH according to customer specifications. ProSign is a company which is focused on the development of graphical engineering systems based on the programming system iCon-L for industrial process and control systems. Moreover, ProSign delivers comprehensive automation solutions composed of software and hardware for complex customer requirements and is able to undertake the support of the particular project solution at the customer site. The practical application and a simple and intuitive operation are important for every project solution.

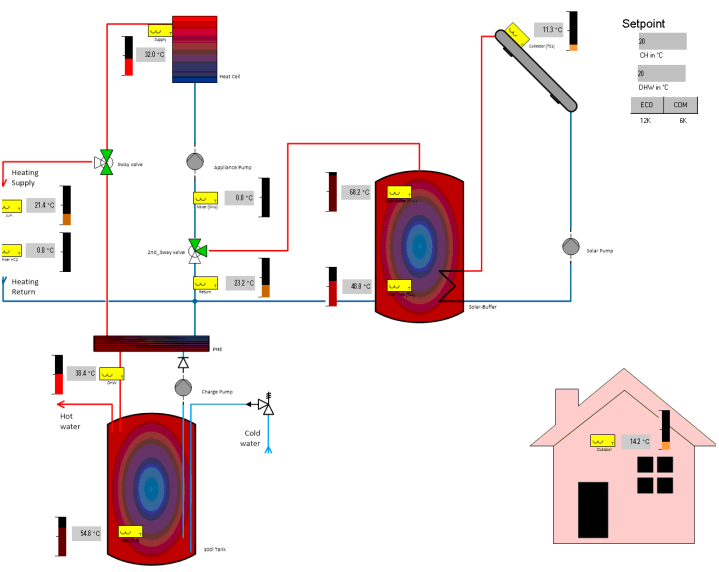

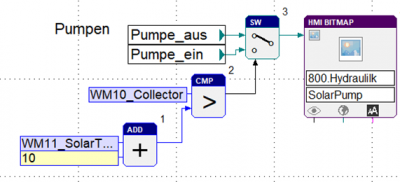

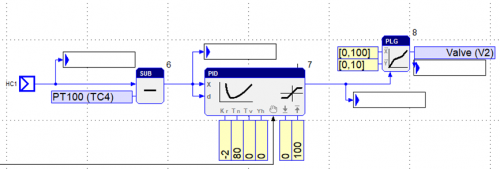

In this particular case, the test.con application will be used, which was especially developed for the test controllers from Gantner Instruments. The descriptive language of this programming system allows engineers and technicians to work in an environment which corresponds to a familiar view on technical and physical systems. With the mask designer, the user can design his own HMI (user interface) which contains the controls and indicators to be shown on the touchscreen of the test controller.

ProSign also supplied the resistive matrix controlled by CAN to simulate temperatures. In addition to pure temperature simulation, a system test and an exhaust gas simulation are also possible using this system. Besides to reading input data in the CSV format, valves are controlled and the resistance matrices as well as a stepper motor are addressed via CAN. The most important information for the customer is visualized on a screen using hydraulic schemes. Furthermore, a running experiment can be influenced by various settings.